Choose CROMA for your hot wire foam cutting table supply and you will be assured of getting the best features for your equipment. Just with the same care we take with our other machines, we are customer service oriented and we will adapt to your needs and your process so that you are completely satisfied.

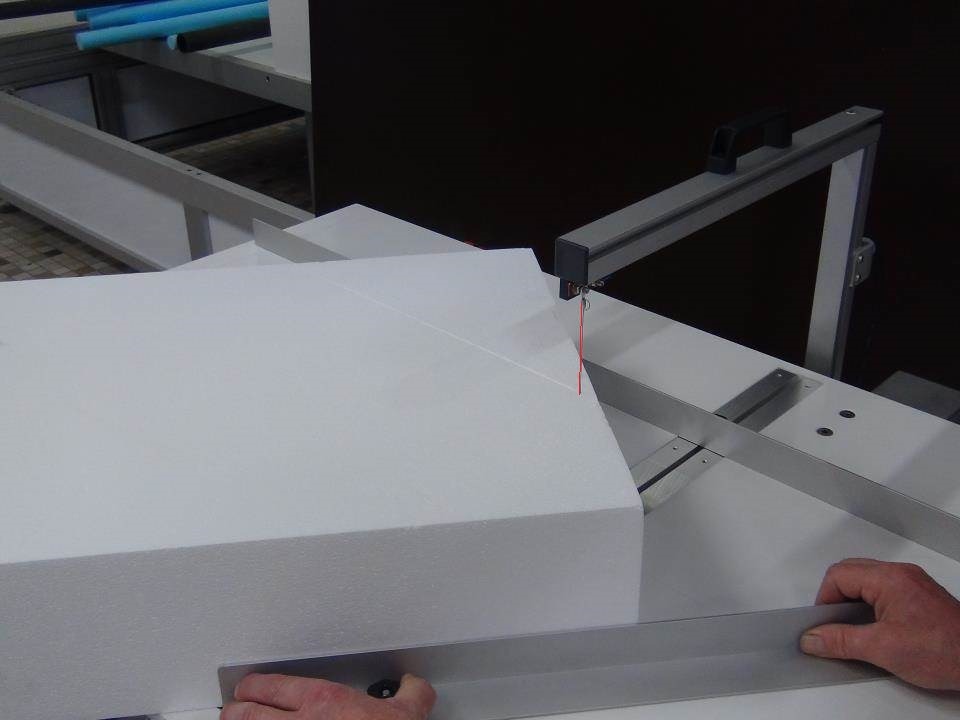

Clean, dust free and noiseless, the hot wire cutting process guarantees a safe process for the operator and the best surface quality for your foams and other thermofuse materials. Polystyrene blocks, extruded insulation boards, polyethylene cornices, mold parts, packaging elements, on an daily basis or very occasionally, in your workshop or on a construction site, this table will fit any of your manual cutting need.

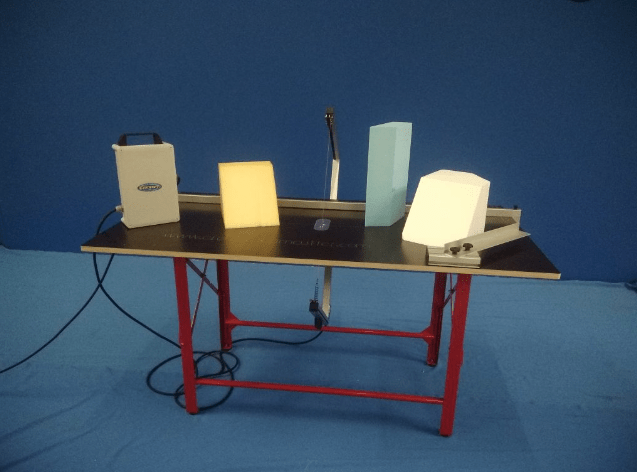

The mechanically welded frame supports an engraved wooden table with dimension and radius graduations allowing the material to be precisely positioned against the guides. Manufactured in our French facility, we focus on the hot wire foam cutting table’s reliability and robustness while remaining light enough to be moved from one place to another.

If you have any questions or need for custom features, please contact us so we can discuss it.

©2022 - CROMA : Cutting machine -

Agence de communication Morgane