Automatic EPS cornice covering line

How can you apply a coating on an EPS cornice efficiently with a smooth and homogenous surface result? This question led CROMA to design and build its coating machine to cover polystyrene profiles and cornices with different coating products.

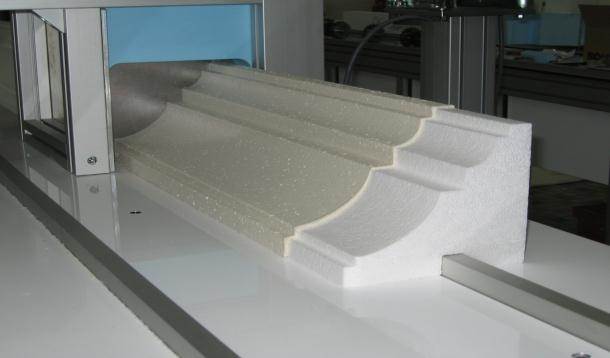

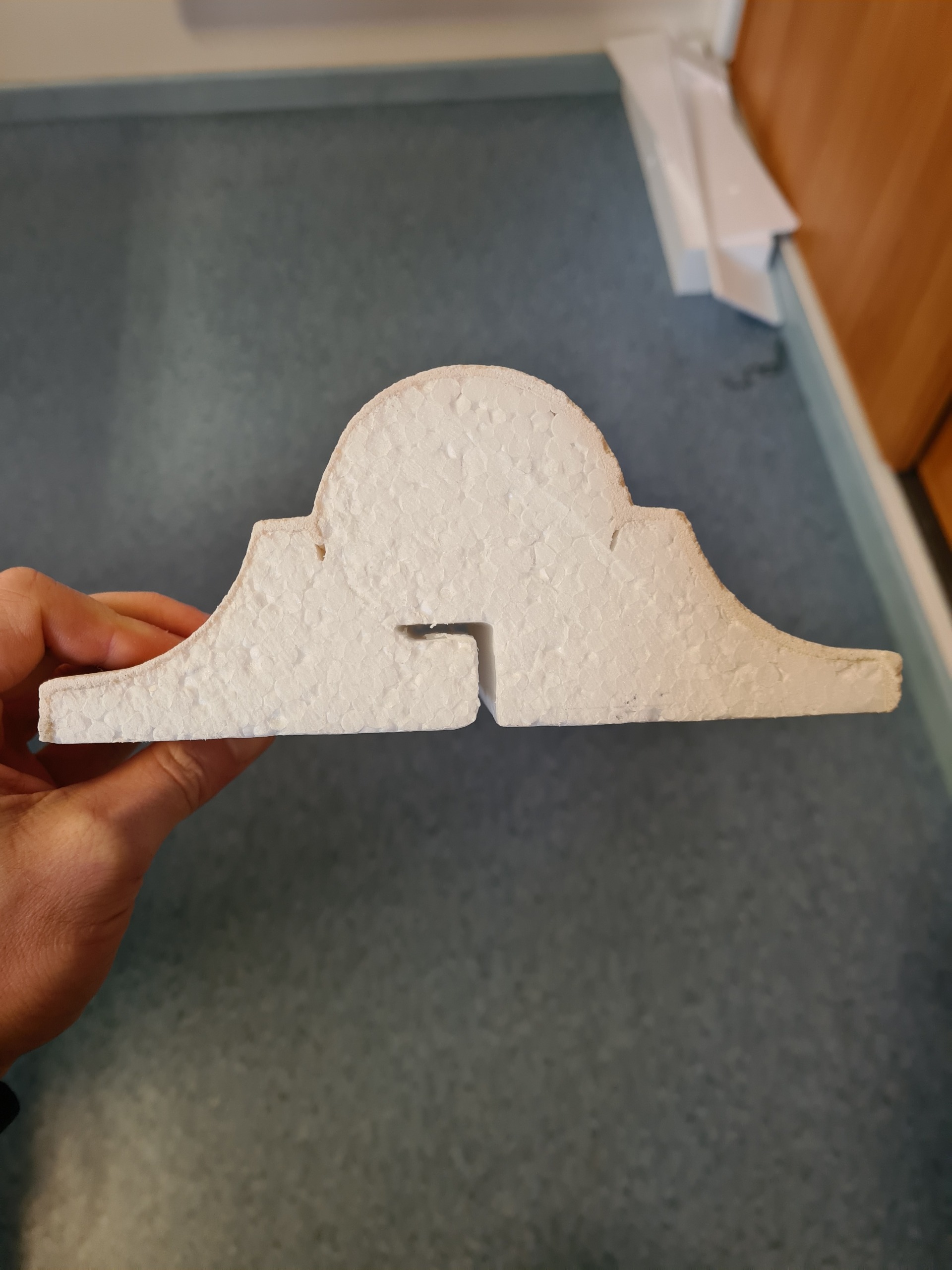

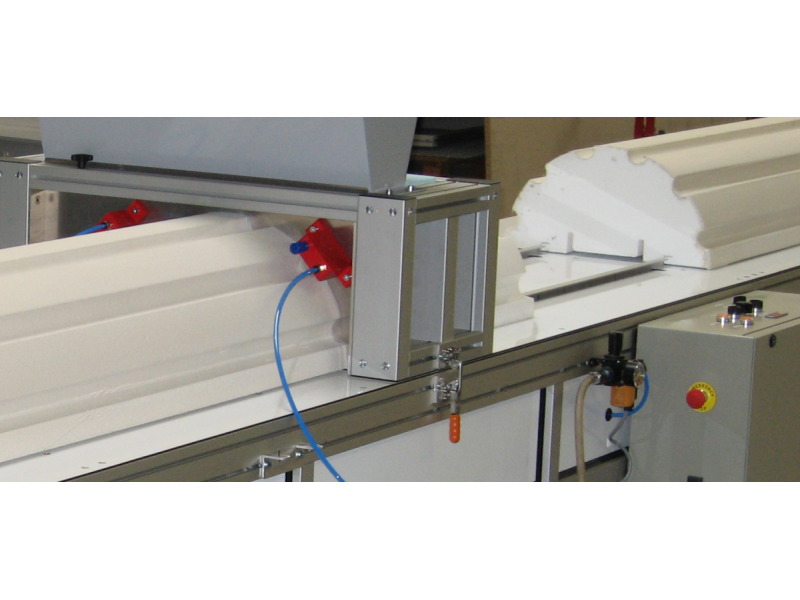

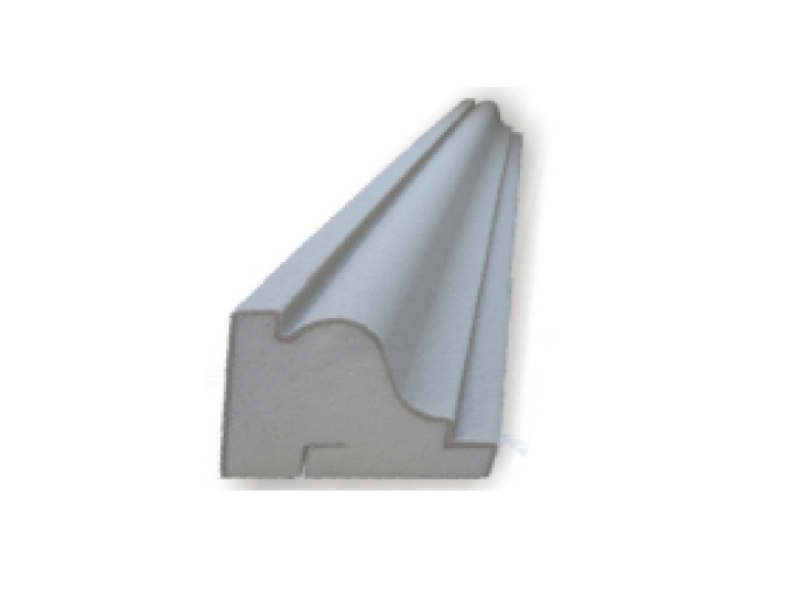

First the parts to be coated will have an “L” shape cut on the bottom side so that they can be driven by the coating machine rail through the coating chamber. The chamber has a hopper on top, in which the operators will display the coating product. An aluminum knife at the exit of the coating chamber, cut with the shape of the profile to be coated, will ensure that the excess material is removed so that you get a consistent and smooth deposit with a high finish. Fully automated, the coating line has built in sensor cells that will stop the process when there is no more product to be coated.

From the panel board, you can adjust the advance speed to adapt the production to the desired result.

Very large cornices and profiles can be coated with the XL model, designed for shapes as large as 1.2 meters and 62 cm high.

The double rail on the coating line can be used either for driving large parts, or to improve productivity and operate two lines of EPS cornices simultaneously. With this process, coating EPS profiles is fast and easy on an industrial scale.